What is PU Coating?

PU coating is a type of polymer coating that consists of a polyurethane layer applied to a substrate. The polyurethane layer can be applied in various thicknesses, depending on the application and the desired level of protection.

PU coatings can be applied to a wide range of surfaces, including metals, plastics, wood, and concrete. They provide excellent resistance to wear and tear, chemicals, and abrasion, making them ideal for applications that require high levels of protection.

The History of PU Coatings

PU coatings were first developed in the 1930s, by German chemist Dr. Otto Bayer. The first commercial applications of PU coatings were in the automotive industry, where they were used to provide a protective layer over car bodies.

Over the years, the development of PU coatings has continued, and they are now used in a range of industries, including aerospace, construction, textiles, and furniture.

How Does PU Coating Work?

PU coatings work by forming a protective layer over a substrate. The polyurethane layer provides excellent resistance against wear and tear, chemicals, and abrasion, helping to extend the life of the substrate.

PU coatings can be applied using a range of techniques, including spraying, brushing, and rolling. The thickness of the coating can be adjusted depending on the application and the level of protection required.

Types of PU Coatings

There are three main types of PU coatings:

Solvent-based PU Coatings

Solvent-based PU coatings are made up of a polyurethane layer that is dissolved in a solvent. The solvent is used to thin the coating, making it easier to apply. Once the coating is applied, the solvent evaporates, leaving behind a protective layer.

Solvent-based PU coatings are known for their high levels of durability and resistance to wear and tear. They are commonly used in the automotive industry, where they provide protection against chemicals, abrasion, and weather.

Water-based PU Coatings

Water-based PU coatings are made up of a polyurethane layer that is dissolved in water. They are often used in applications where solvent-based coatings are not suitable, such as in the food industry.

Water-based PU coatings are known for their low levels of VOC emissions, making them a more environmentally friendly option than solvent-based coatings. They also provide excellent resistance against wear and tear, chemicals, and abrasion

Powder-coated PU Coatings

Powder-coated PU coatings are made up of a polyurethane layer that is applied in a powder form. The powder is electrostatically charged, causing it to stick to the substrate. The coated substrate is then baked, causing the powder to melt and form a protective layer.

Powder-coated PU coatings are known for their excellent resistance against wear and tear, chemicals, and abrasion. They are commonly used in the construction industry, where they provide protection against weather and corrosion.

Benefits of PU Coatings

PU coatings offer a range of benefits, including:

Durability

PU coatings are known for their high levels of durability, making them ideal for applications that require long-lasting protection.

Flexibility

PU coatings are flexible and can withstand a range of temperatures and weather conditions. They are also resistant to cracking and peeling, even in extreme conditions.

Chemical Resistance

PU coatings provide excellent resistance against a range of chemicals, including acids, alkalis, and solvents. This makes them ideal for applications in industries such as automotive and aerospace, where exposure to chemicals is common.

Weather Resistance

PU coatings provide excellent resistance against weather conditions, including UV radiation, moisture, and temperature fluctuations. This makes them ideal for applications in industries such as construction and textiles.

Applications of PU Coatings

PU coatings are used in a wide range of industries, including:

Automotive

PU coatings are commonly used in the automotive industry, where they provide protection against wear and tear, chemicals, and abrasion. They are used to coat car bodies, wheels, and engine parts.

Aerospace

PU coatings are used in the aerospace industry, where they provide protection against the harsh conditions of space travel. They are used to coat spacecraft and satellites.

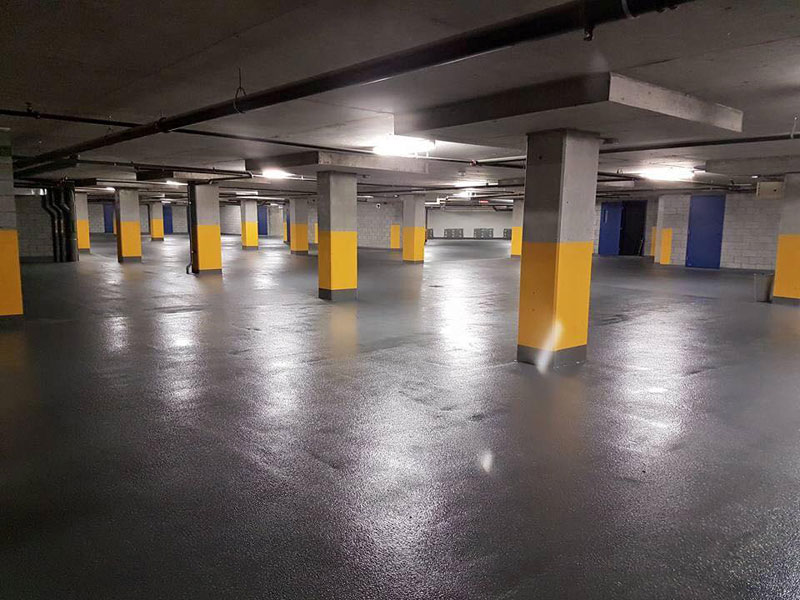

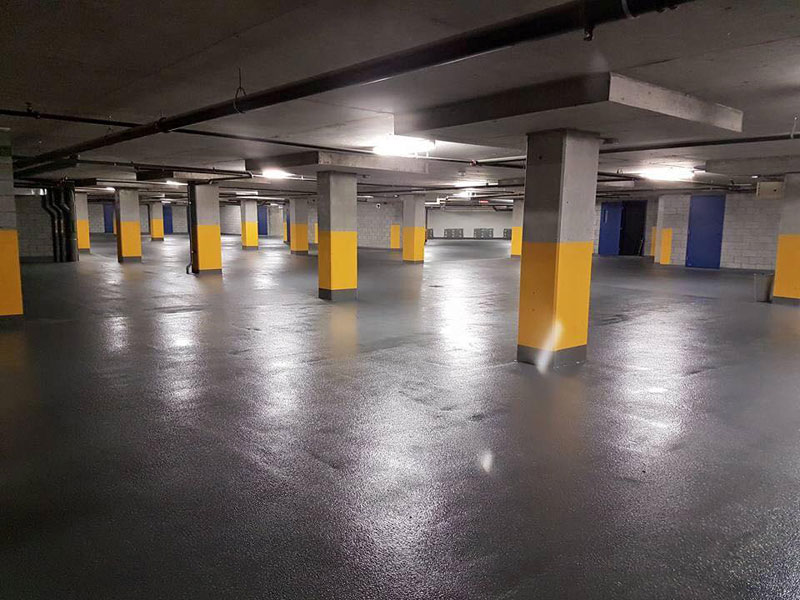

Construction

PU coatings are used in the construction industry, where they provide protection against weather and corrosion. They are used to coat buildings, bridges, and pipelines.

Textiles

PU coatings are used in the textiles industry, where they provide waterproofing and durability. They are used to coat fabrics such as tents, awnings, and outdoor gear.

Furniture

PU coatings are used in the furniture industry, where they provide durability and resistance against wear and tear. They are used to coat furniture such as sofas, chairs, and tables.

How to Apply PU Coatings

PU coatings can be applied using a range of techniques, including spraying, brushing, and rolling. The substrate should be clean and free of any dust, dirt, or debris before applying the coating.

The thickness of the coating should be adjusted depending on the application and the level of protection required. It is important to follow the manufacturer's instructions when applying PU coatings to ensure proper adhesion and protection.

Maintenance and Care of PU Coatings

PU coatings require minimal maintenance and care. They should be cleaned regularly using a mild detergent and a soft cloth. Avoid using harsh chemicals or abrasive materials, as these can damage the coating.

If the coating becomes damaged, it can be repaired using a patching kit or by recoating the affected area.

Conclusion

PU coating is a versatile and durable protective coating that is widely used in a range of industries. It provides excellent resistance against wear and tear, chemicals, abrasion, and weather, making it ideal for applications that require high levels of protection.

Whether you're in the automotive, aerospace, construction, textiles, or furniture industry, PU coatings offer a range of benefits that can help extend the life of your products and protect them from damage. So, consider incorporating PU coatings into your products and see the difference for yourself!

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

Беларуская мова

Basa Jawa