H06-5 Epoxy Zinc-rich Primer

This two-component product is mainly prepared by epoxy resin, ultra-fine zinc powder, and polyamide as curing agent. This product features:

H06-5 Epoxy Zinc-rich Primer Video

H06-5 Epoxy Zinc-rich Primer

Basic Technical Datasheet

Appearance | Grey, matt |

Density, kg/L | ~2.30 |

Flash point, ℃ | Part A: 24 Part B: 27 |

Zinc content | ≥ 60 % |

Impact resistance, cm | 50 |

Adhesion, MPa | ≥6 |

Pot life, h @ 23 ± 2 ℃ | ≥5 |

Theoretical spreading rate, kg/m2 @ 80 µm dry film | 0.3 |

VOC, g/L | 420 |

|

H06-5 Epoxy Zinc-rich Primer Product Packaging

Packaging:

Part A: 30 kg in a 20-liter iron barrel Part B: 3 kg in a 5-liter iron barrel. Shelf Life: Part A: 12 months Part B: 12 months If exceeding shelf life, the products shall be tested before using.

|

H06-5 Epoxy Zinc-rich Primer

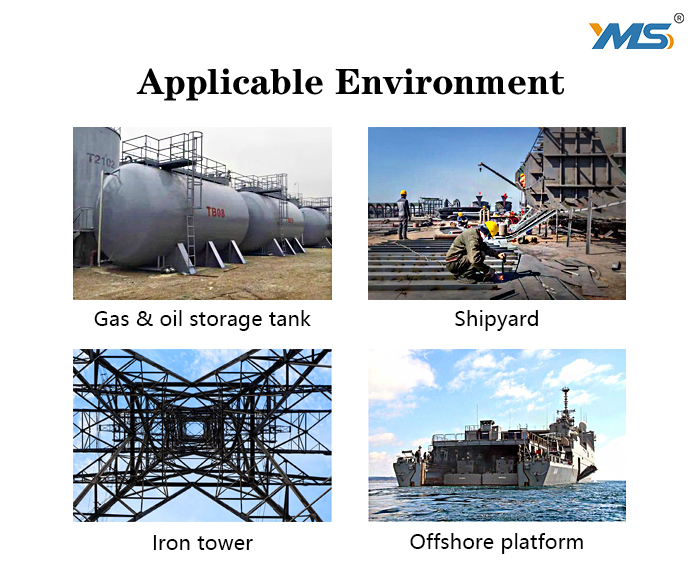

Applicable Environment

|  |  |  |

Boat | gas storage tank | oil storage tank | galvanized workpiece |

|  |  |  |

Offshore platform | Iron tower | Shipyard | Bridge |

H06-5 Epoxy Zinc-rich Primer

Compatibility

| Product | Thickness |

| Primer: | H06-5 Epoxy Zinc Rich Primer | 2*40 µm |

| Midcoat: | H53-6 Epoxy Mica Iron Oxide Paint | 150 µm |

| Topcoat: | BS52-10 Acrylic Polyurethane Finish Paint | 2*40 µm |

H06-5 Epoxy Zinc-rich Primer

Finished Projects

H06-5 Epoxy Zinc-rich Primer

Production Process

H06-5 Epoxy Zinc-rich Primer

Instructions For Use

Substrate Treatment:

All surface shall be clean, dry and free from any contaminations to achieve long lasting function.

Carbon Steel

Minimum St 3 (ISO 8501-1)

Optimum Sa 2½ (ISO 8501- 1)

Primed steel

Blasted to Sa 2 (ISO 8501- 1)

Instructions for Use:

Mixing

Mix part A and part B as 30:3 by weight. Slowly add part B into part A and ensure mixed completely.

Thinner

X-7 Epoxy paint thinner ≤ 10 % w./w.

Cleaner

X-7 Epoxy paint thinner

Application methods:

Airless spray (recommended): Nozzle tip: 0.015-0.021 inch, minimum 150 bar/2100 psi

Brush: recommended for small areas only.

Roller: recommended for small areas only.

H06-5 Epoxy Zinc-rich Primer

Company Introduction

H06-5 Epoxy Zinc-rich Primer

Exhibitions

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

Беларуская мова

Basa Jawa