Ethylene Phosphating Primer

This two-component product is composed of polyvinyl butyral, anti-rust pigment, solvent and phosphating solution.It has the following resistance characteristics:

Ethylene Phosphating Primer Video

Ethylene Phosphating Primer Basic Technical Datasheet

Color

|

Light yellow |

Gloss |

No gloss |

Density | ~1.2Kg/L |

Solid Volume |

(45±2 )% |

Standard Film thickness |

30um dry film thickness (about 67um wet film thickness) |

Theoretical spreading rate | 12.5m²/Kg (100um dry film thickness) |

Flash Point | 15℃ |

|

Ethylene Phosphating Primer Product Packaging

Packaging:

part A:18kg in a 20-liter iron bucket. part B:4kg in a 5-liter iron bucket. Shelf Life:

12 months If exceeding shelf life, the products shall be tested before using.

|

Ethylene Phosphating Primer Applicable Environment

|  |  |  |

Bridge |

Storage tank | Ship | Instrument |

Ethylene Phosphating Primer Compatibility

| Product | Thickness |

Primer: |

Ethylene Phosphating Primer

| 1*30 µm (dry film thickness)

|

| Paint: | Epoxy Intermediate Paint

| 2*50 µm (dry film thickness) |

| Topcoat: |

Epoxy Topcoat

| 2*40 µm (dry film thickness) |

Ethylene Phosphating Primer Finished Projects

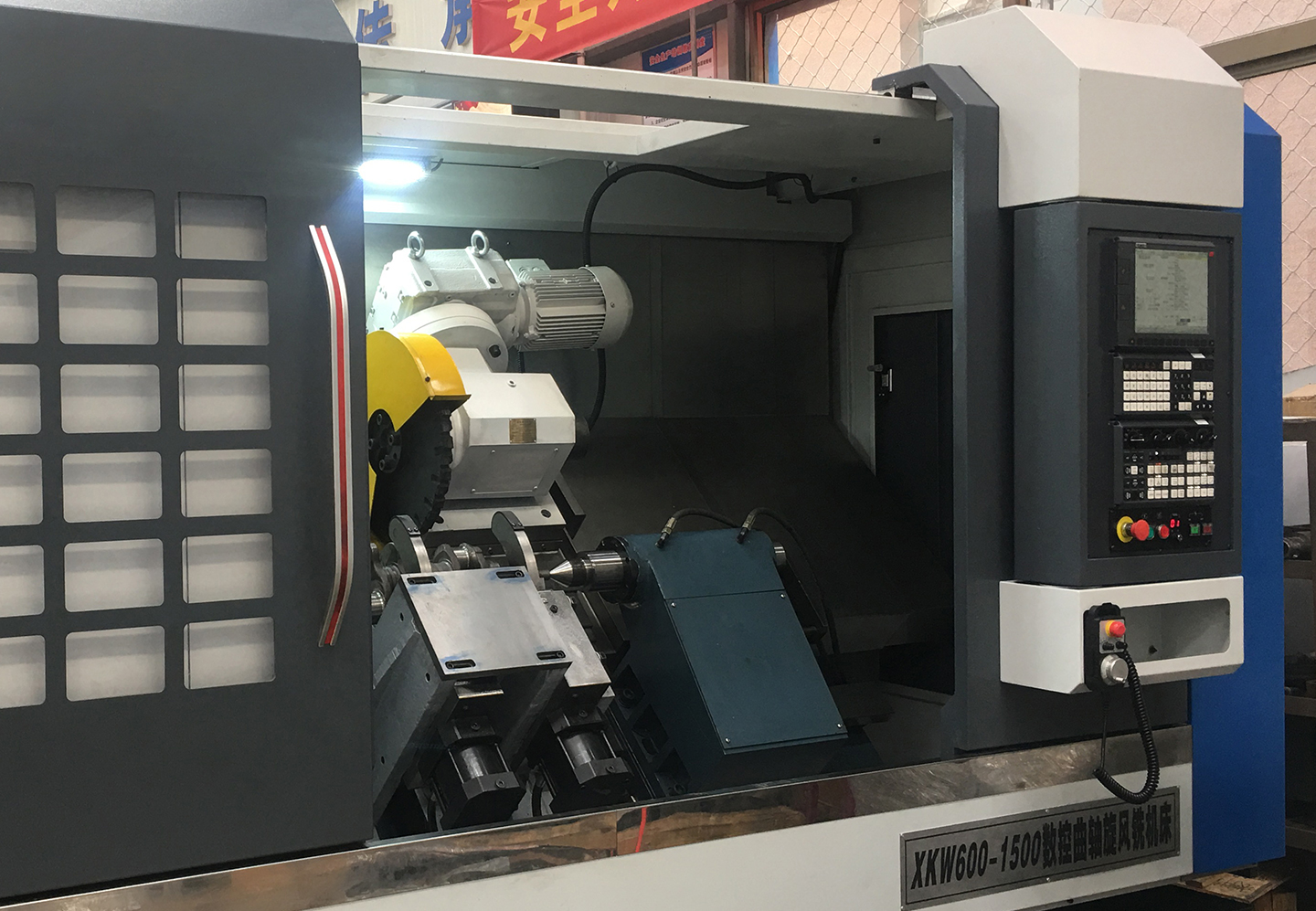

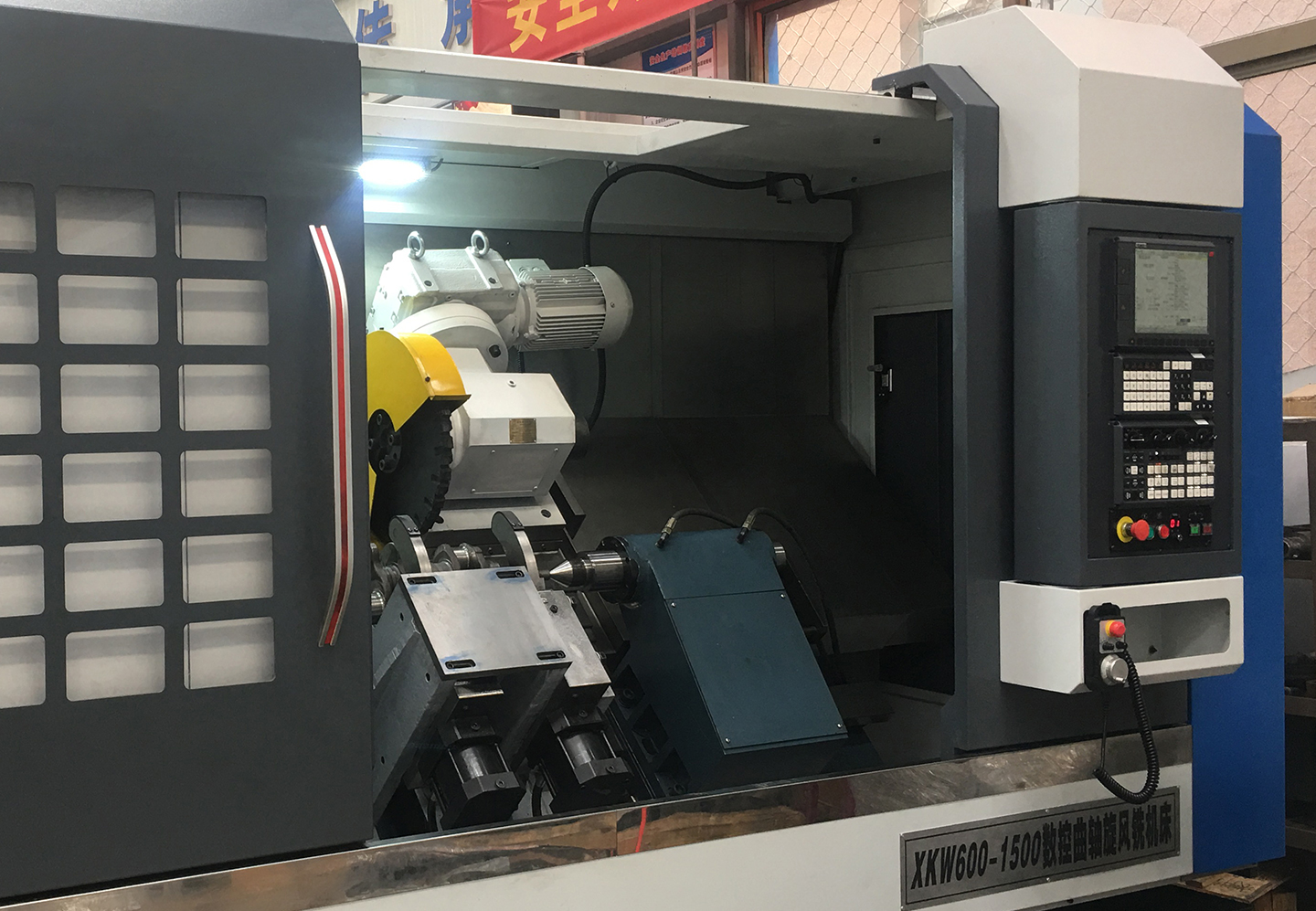

Ethylene Phosphating Primer Production Process

Ethylene Phosphating Primer Instructions For Use

Substrate Treatment:

The surface to be coated shall be clean, dry and free from contaminations. Also, the surface shall be evaluated and treated according to ISO8504 standard.

Bare steel: sandblasting to reach Sa2.5(IOS8501-1:2007). For the non-soaking site, acceptable for power tool grinding, at least reach St2(IOS8501-1:2007).

Instructions for Use:

Mixing:

Mixing:

Use the power mixer to mix the main paint evenly, and then as you stir it, you add the hardener until you get to mix well.

Thinner:

Thinner:

Exclusive thinner

Nozzle tip: 0.017~0.023 inches

Spray pressure: 15~18Mpa

Thinner ratio: 0~15% (by weight of paint)

Recommended

Ethylene Phosphating Primer Company Introduction

Ethylene Phosphating Primer Exhibitions

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

Беларуская мова

Basa Jawa