Waterborne Acrylic Finish

This one-component product is composed of waterborne acrylic resin, water, pigments with great weather and corrosion resistance. Taking water as the dispersing media, this environmental friendly paint is nonflammable and nonexplosive.This product features:

70-100secs (viscosity cup 4, 23±2 ℃)

Waterborne Acrylic Finish Video

Waterborne Acrylic Finish Basic Technical Datasheet

Color | Customized |

Gloss | Flat |

Density | ~1.25Kg/L |

Solid Volume | (40±2 )% |

Standard Film thickness | 60um dry film thickness (about 150um wet film thickness) |

Theoretical spreading rate | 5.3m²/Kg (60um dry film thickness) |

Adhesion | Level 1 |

|

Waterborne Acrylic Finish Product Packaging

Packaging:

22kg in a 20-liter iron barrel Shelf Life: 12 months If exceeding shelf life, the products shall be tested before using.

|

Waterborne Acrylic Finish Applicable Environment

|  |  |  |

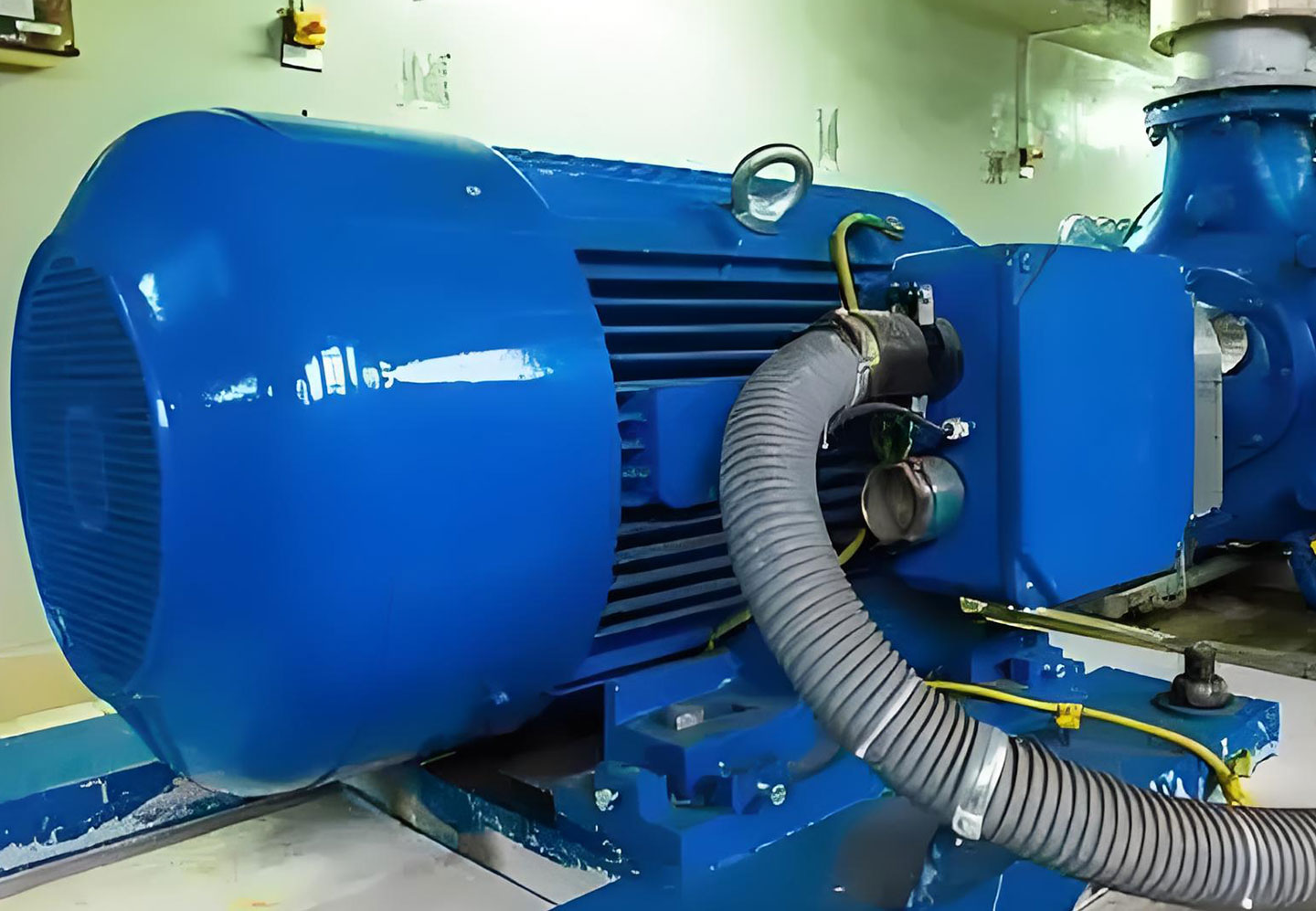

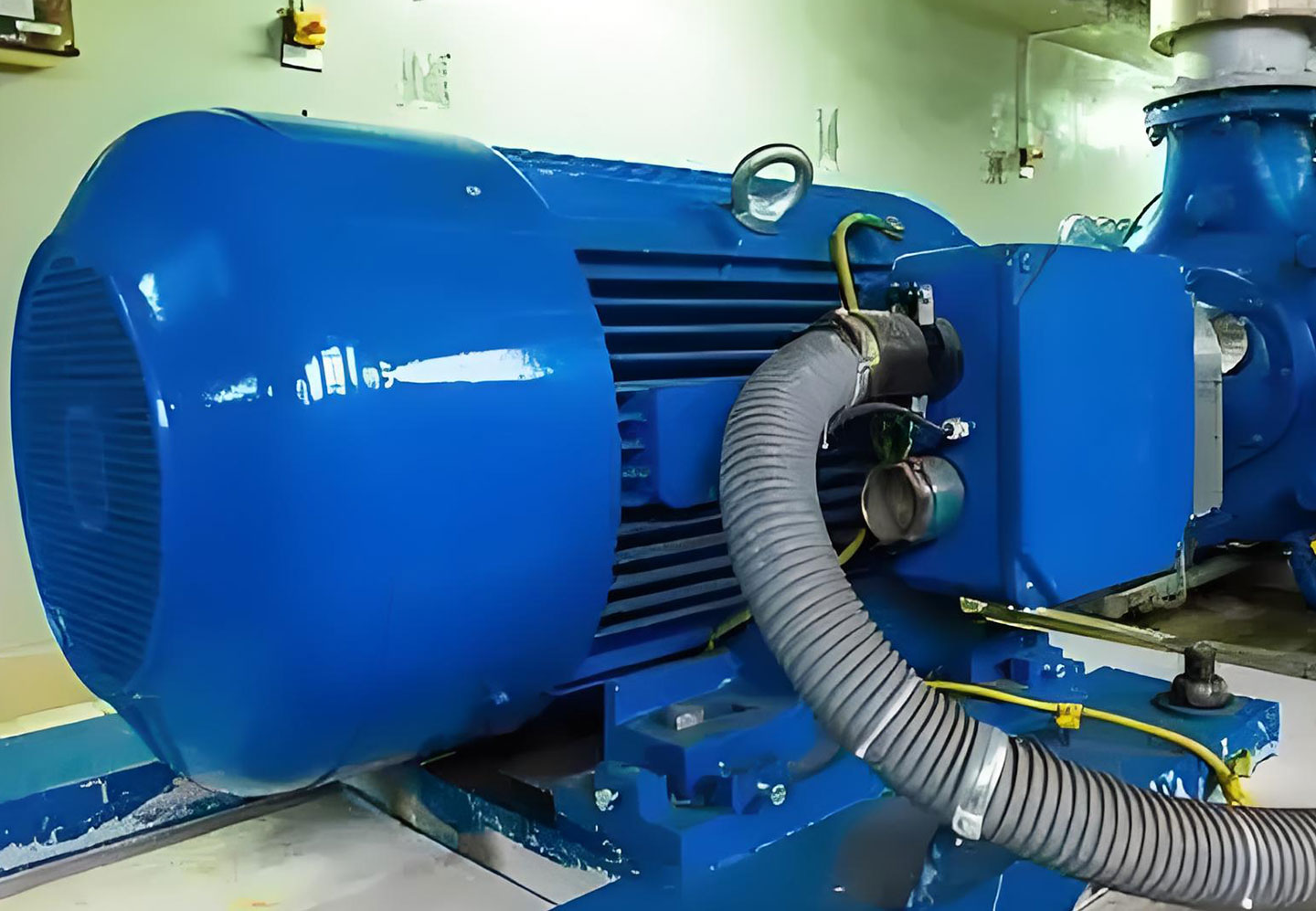

Apparatus | Vessel | Bridges | Mechanical and electrical products |

Waterborne Acrylic Finish Compatibility

| Product | Thickness |

| Primer: | Waterborne Zinc-rich Epoxy Primer | 2*40 µm |

| Midcoat: | Waterborne Epoxy Intermediate Paint | 2*40 µm |

| Topcoat: | Waterborne Acrylic Finish | 2*30 µm |

Waterborne Acrylic Finish Finished Projects

Waterborne Acrylic Finish Production Process

Waterborne Acrylic Finish Instructions For Use

Substrate Treatment:

The surface to be coated shall be clean, dry and free from contaminations. Also, the surface shall be evaluated and handled according to ISO8504 standard.

Painted surface: only apply to clean, dry and intact compatible primer.

Instructions for Use:

Mixing:

Ready to use

Thinner:

Clean water

Thinner ratio:

Add 10% water by weigh of paint, or make adjustment according to specific condition, but the maximum should not exceed 20%.

Airless spray:

Nozzle tip: 0.017~0.023 inches

Spray pressure: 15~18Mpa

Spray viscosity:

60-80 secs

Roll viscosity:

70-100secs (viscosity cup 4, 23±2 ℃)

Brush, Roller:

Use soft wool brush or roller

Recommended

Must achieve required thickness

Waterborne Acrylic Finish Company Introduction

Waterborne Acrylic Finish Exhibitions

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

Беларуская мова

Basa Jawa