| Acrylic Resin Copolymer Polymer Sweep Stick Product Details

The Copolymer Polymer Sweep Stick, made of solid acrylic copolymer, is a high - performance additive specially designed for water - based drilling fluids. 20 sweep sticks are neatly stored in each 6 - gallon metal container, ensuring the quality and storage safety of the product from the source. This product is packaged and transported in strict accordance with the standards of the Saudi Aramco Export Packing Manual, ensuring the safe and efficient circulation of the product worldwide.

| Acrylic Resin Copolymer Polymer Sweep Stick Core Functions

1. Viscosity Increase:Effectively enhance the viscosity of the drilling fluid, optimize the fluid performance, and ensure the stability of the drilling process.

2. Friction Reduction:Significantly reduce the friction within the fluid and between the fluid and the drilling tools, minimize energy consumption, and improve operational efficiency.

3. Cuttings Encapsulation:Tightly encapsulate the drill cuttings to prevent their redispersion in the drilling fluid, facilitating subsequent cleaning.

4. Fluid - Loss Control:Effectively control the fluid - loss volume of the drilling fluid, maintain the stability of the wellbore, and ensure the smooth progress of the drilling operation.

| Acrylic Resin Copolymer Polymer Sweep Stick Usage Guide

During the drill string connection operation, directly drop the Copolymer Polymer Sweep Stick into the drill string. The sweep stick will quickly take effect and form a high - viscosity sweeping fluid, effectively replacing the traditional high - viscosity mud sweep method and providing a more efficient and stable sweeping solution for the drilling operation.

| Acrylic Resin Copolymer Polymer Sweep Stick Technical Specifications

Item | Parameter |

Appearance | A tube filled with polymer |

Size | 1 - 1/4×15 inches |

Specific Gravity (68°F/20°C) | 1.85 - 1.99 |

Solubility | Soluble in water |

| Acrylic Resin Copolymer Polymer Sweep Stick Quality Assurance

Saudi Aramco reserves the right to conduct spot checks and laboratory tests on the products to ensure that they fully meet the material description and specification requirements. For each batch of products leaving the factory, the manufacturer and/or supplier must attach a Laboratory Certificate of Analysis (COA) and a Certificate of Origin (COO) to ensure product quality from the source.

| Acrylic Resin Copolymer Polymer Sweep Stick Product Labeling

The product name, batch number, production date, expiration date, SAP number, country of origin, manufacturer's name, and contact information are clearly marked on the product packaging. At the same time, hazard information is labeled in strict accordance with the Material Safety Data Sheet (MSDS) to ensure the safe use of the product by users.

| Acrylic Resin Copolymer Polymer Sweep Stick Packaging and Transportation

1. Packaging:Heavy - duty plastic pallets are selected, with dimensions of 120×120×15 cm, double - deck structure, four - way entry, and features such as stackability, anti - slip, chemical resistance, weather resistance, hygiene, and recyclability. The pallets must be certified by an independent materials testing agency recognized by Saudi Aramco in accordance with ISO 8611 and MS 8314 - 05 pallet packaging specifications to ensure that the minimum static load capacity meets the standards.

2. Transportation:The transportation process strictly follows the relevant regulations of the Saudi Aramco Export Packing Manual to ensure that the product is not damaged during transportation and is safely delivered to the destination.

| Acrylic Resin Copolymer Polymer Sweep Stick Comment & FAQ

1. Who are we?

About Us We are headquartered in Jiangsu, China, established in 2016, and our market reach extends to Southeast Asia (40.00%), Africa (15.00%), Eastern Europe (15.00%), Western Europe (10.00%), the Middle East (10.00%), North America (5.00%), and the Domestic Market (5.00%). Our team comprises approximately 51-100 dedicated professionals.

2. How can we guarantee quality?

Ensuring the highest quality is our priority. We achieve this by: Conducting pre-production samples before mass production.

Carrying out thorough final inspections before shipment.

3. What can you buy from us?

Our product range includes a variety of offerings such as Alkyd Paint, Polyurethane Paint, Epoxy Paint, Acrylic Paint, Organic Silicone Paint, and more.

4. Why should you buy from us not from other suppliers?

There are several compelling reasons to opt for our products:We possess a rich 22-year history dedicated to the development, production, and sales of heavy anti-corrosion coatings.

We hold the prestigious designation as the developer for a military unit and are located within the Changzhou state high technology industrialization base for new paint.

Our commitment to quality is underscored by ISO9001, ISO14001, and OHSAS18001 certifications.

5. What services can we provide?

We offer the following services:Accepted Delivery Terms: FOB, EXW

Accepted Payment Currency: USD

Accepted Payment Type: T/T

Multilingual Support: English and Chinese

Feel free to reach out to us for all your coating needs, and we will be delighted to assist you.

| Acrylic Resin Copolymer Polymer Sweep Stick Production Process

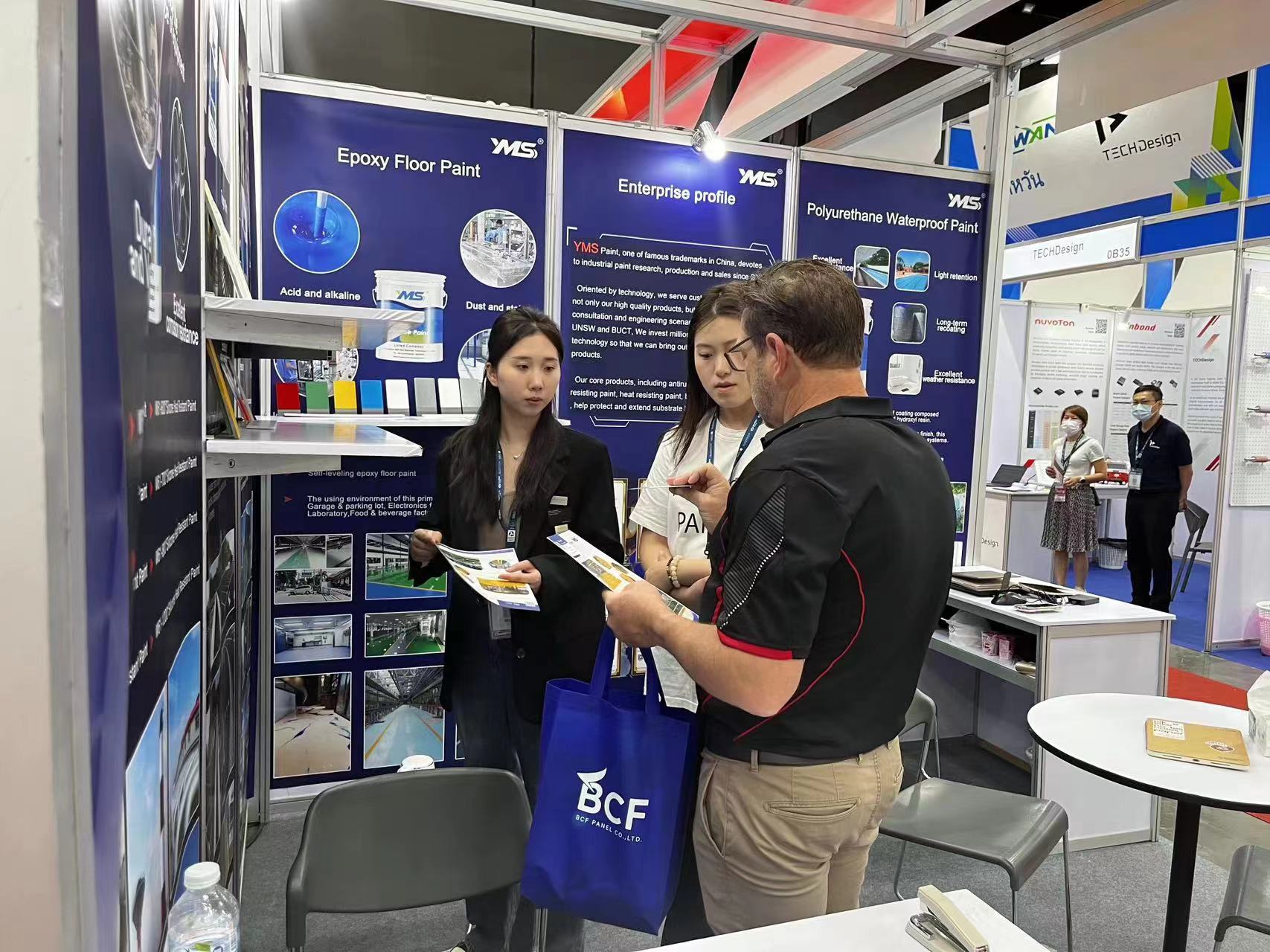

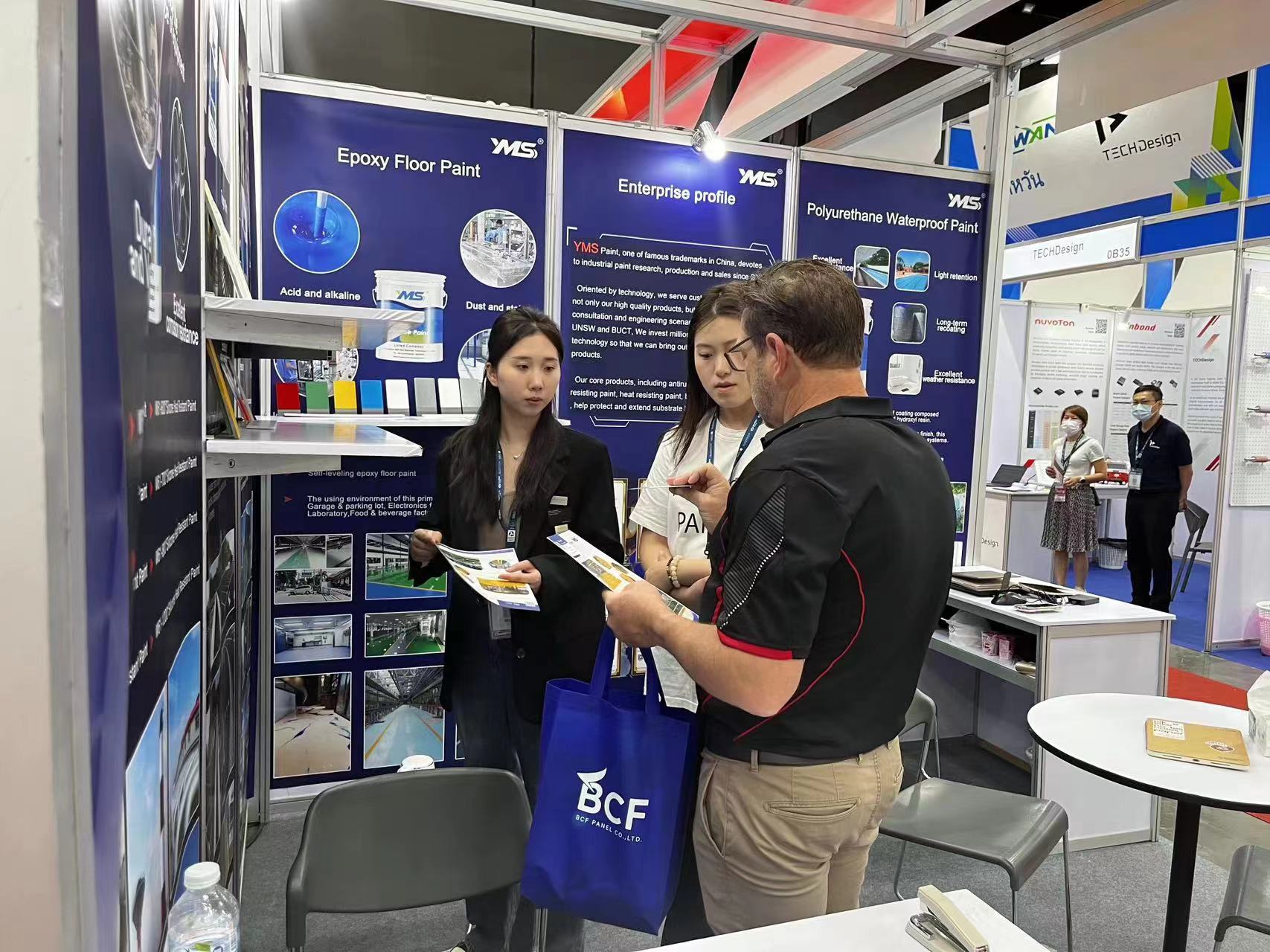

Epoxy Resin Glue KE-452 Factory show.

| Acrylic Resin Copolymer Polymer Sweep Stick Certifications

| Acrylic Resin Copolymer Polymer Sweep Stick Instructions For Use

Mix part A and part B as 15:5 by weight. Slowly add part B into part A and ensure mixed completely.

X-10 polyurethane paint exclusive thinner ≤ 10 % w./w.

X-10 polyurethane paint exclusive thinner

Airless Spray: Pressure : 1800 - 2700 psi ,Hose: 1/4" ID, Tip:.015" - .021".

Filter: 60 mesh.

Brush :. Nylon / polyester.

Roller:1/4 - 1/2" woven.

Apply certain amount of sealing agent to further smooth surface of substrate with airless spraying or rolling.

Towel two layers of polyurethane slurry (a rough layer followed by a fine the layer) on the surface to required thickness. Before toweling second layer, smooth the first layer by grinding.

Grind the intermediate layer and clean up extra sands or quartz on intermediate layer, thereafter apply finish coat.

Acrylic Polyurethane Floor PaintAcrylic Polyurethane Floor PaintAcrylic Polyurethane Floor PaintAcrylic Polyurethane Floor PaintAcrylic Polyurethane Floor PaintAcrylic Polyurethane Floor PaintAcrylic Polyurethane Floor PaintAcrylic Polyurethane Floor PaintAcrylic Polyurethane Floor PaintAcrylic Polyurethane Floor PaintAcrylic Polyurethane Floor PaintAcrylic Polyurethane Floor PaintAcrylic Polyurethane Floor PaintAcrylic Polyurethane Floor Paint

| Acrylic Resin Copolymer Polymer Sweep Stick Company Profile

YMS Paint, one of famous trademarks in China, devotes to industrial paint research, production and sales since 2001.

Oriented by technology, we serve customers worldwide not only our high quality products, but also technical consultation and engineering scenarios. Cooperating with UNSW and BUCT, We invest millions to update our technology so that we can bring out better and cheaper products.

Our core products, including antirust paint, acid & alkali resisting paint, heat resisting paint, building & floor paint etc., help protect and extend substrate life for years.

| Acrylic Resin Copolymer Polymer Sweep Stick Exhibitions

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

Беларуская мова

Basa Jawa