Product Description

This product is based on epoxy resin and coal tar pitch, added with ultra-fine pigment, filler and new additive. This product contains two parts: part A is the main paint and part B is the curing agent, among which the part B can be used for both primer and finish. This two-component epoxy coating can be cured at low temperature with construction temperature ranging from -10℃ to 36℃. The paint’s firm film is resistant to abrasion, sea water, and crude oil.

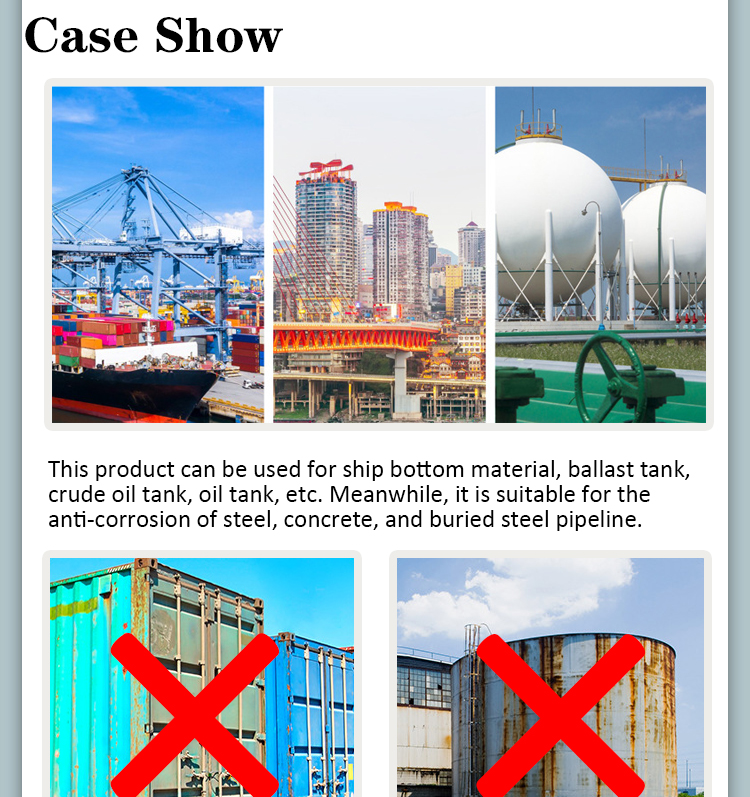

Typical Uses

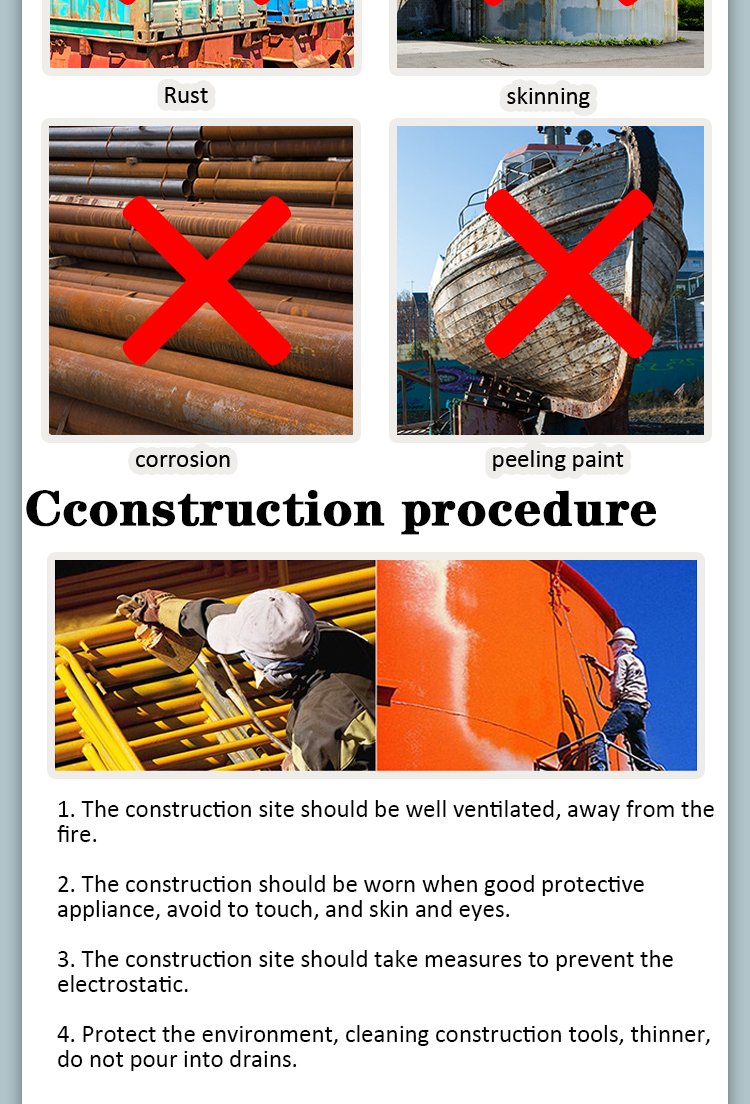

This product is able to provide long-term protection to steel in severe corrosive environment such as the bottom of ships and boats, crude oil tanks, ballast tanks and the outer wall of various buried steel pipelines in the cold areas.

Technical details

Color | Color |

Gloss | Glossy |

Density | ~1.38Kg/L(after mixing) |

Hardness | Epoxy asphalt paint curing agent |

Solid Volume

| (70±2 )% |

Standard Film thickness | 150um dry film thickness (about 215um wet film thickness) |

Theoretical spreading rate | 3.38m⊃2;/Kg (150um dry film thickness)

|

Full Cure | (23±2℃)7d |

Flash Point | 27℃ |

Drying Schedule

Substrate Temperature | 10 oC | 20 oC | 30 oC |

| To touch(75um) | 12h | 4h | 3h |

To handle(75um) | 48h | 24h | 24h |

Min. recoating time | 12h | 4h | 3h |

Max. recoating time | 10d | 7d | 5d |

Pot life | 6h | 4h | 2h |

Surface Treatment

All surface to be coated shall be clean and dry. The surface shall be evaluated and treated according to ISO8504 standard.

For bare steel, it shall be sandblasted to reach Sa2.5(iso8501-1:2007) standard. Depending on the environment of the non-immersed part, grinding with power tools is acceptable but shall at least reach St2(iso8501-1:2007) standard.

For shop primed steel, the shop primer shall be clean, dry and approved.

For surface painted coatings, this product can apply only to clean, dry and good compatible primer.

Classical coating system

Epoxy Sealing Primer | 30 µm (dry film thickness) |

Epoxy Coal Tar Pitch Thick Paste Coating for Winter | 2*75 µm (dry film thickness) |

Please inquire JIANBANG Paint for specific coating solutions. |

|

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

Беларуская мова

Basa Jawa