| Epoxy Coal Tar HL52-4 Product Packaging

A:22kg B:22kg

Part A: 22 kg in a 20-liter iron barrel

Part B: 22 kg in a 20-liter iron barrel

| Epoxy Coal Tar Basic Technical Datasheet

Appearance | Black, Semi-gloss |

Density, kg/L | 1.41 |

Flash point, ℃ | 39 |

Volume solids, % | 74 ± 2 |

Adhesion, MPa | ≥ 6 |

Impact resistance, kg.cm | ≥40

|

Flexibility, mm | ≤8 |

Resistance to salt water (3% NaCl), 168h | No change |

Theoretical spreading rate, kg/m2 @ 35µm dry film | 0.18 |

VOC, g/L | 250-300 |

| Epoxy Coal Tar Compatibility

| Product | Thickness |

Primer: | HL52-4 epoxy coal tar primer | 1mm |

Topcoat: | HL52-3Epoxy coal tar finish | 1mm |

| Epoxy Coal Tar Comment & FAQ

1. Who are we?

About Us We are headquartered in Jiangsu, China, established in 2016, and our market reach extends to Southeast Asia (40.00%), Africa (15.00%), Eastern Europe (15.00%), Western Europe (10.00%), the Middle East (10.00%), North America (5.00%), and the Domestic Market (5.00%). Our team comprises approximately 51-100 dedicated professionals.

2. How can we guarantee quality?

Ensuring the highest quality is our priority. We achieve this by: Conducting pre-production samples before mass production.

Carrying out thorough final inspections before shipment.

3. What can you buy from us?

Our product range includes a variety of offerings such as Alkyd Paint, Polyurethane Paint, Epoxy Paint, Acrylic Paint, Organic Silicone Paint, and more.

4. Why should you buy from us not from other suppliers?

There are several compelling reasons to opt for our products:We possess a rich 22-year history dedicated to the development, production, and sales of heavy anti-corrosion coatings.

We hold the prestigious designation as the developer for a military unit and are located within the Changzhou state high technology industrialization base for new paint.

Our commitment to quality is underscored by ISO9001, ISO14001, and OHSAS18001 certifications.

5. What services can we provide?

We offer the following services:Accepted Delivery Terms: FOB, EXW

Accepted Payment Currency: USD

Accepted Payment Type: T/T

Multilingual Support: English and Chinese

Feel free to reach out to us for all your coating needs, and we will be delighted to assist you.

| Epoxy Coal Tar Production Process

Epoxy Coal Tar Factory show

| Epoxy Coal Tar Certifications

| Epoxy Coal Tar Case Show

Epoxy Coal-tar Primer

| Epoxy Coal Tar Instructions For Use

Mixing

Mix part A and part B as 22:22 by weight. Slowly add part B into part A and ensure mixed completely.

Thinner:

X-7 Epoxy paint thinner ≤ 10 % w./w.

Cleaner:

X-7 Epoxy paint thinner

Application methods:

Airless spray (recommended):Nozzle tip: 0.017-0.025 inch, minimum 3000 psi.

Brush: recommended for small areas only.

Roller: recommended for small areas only.

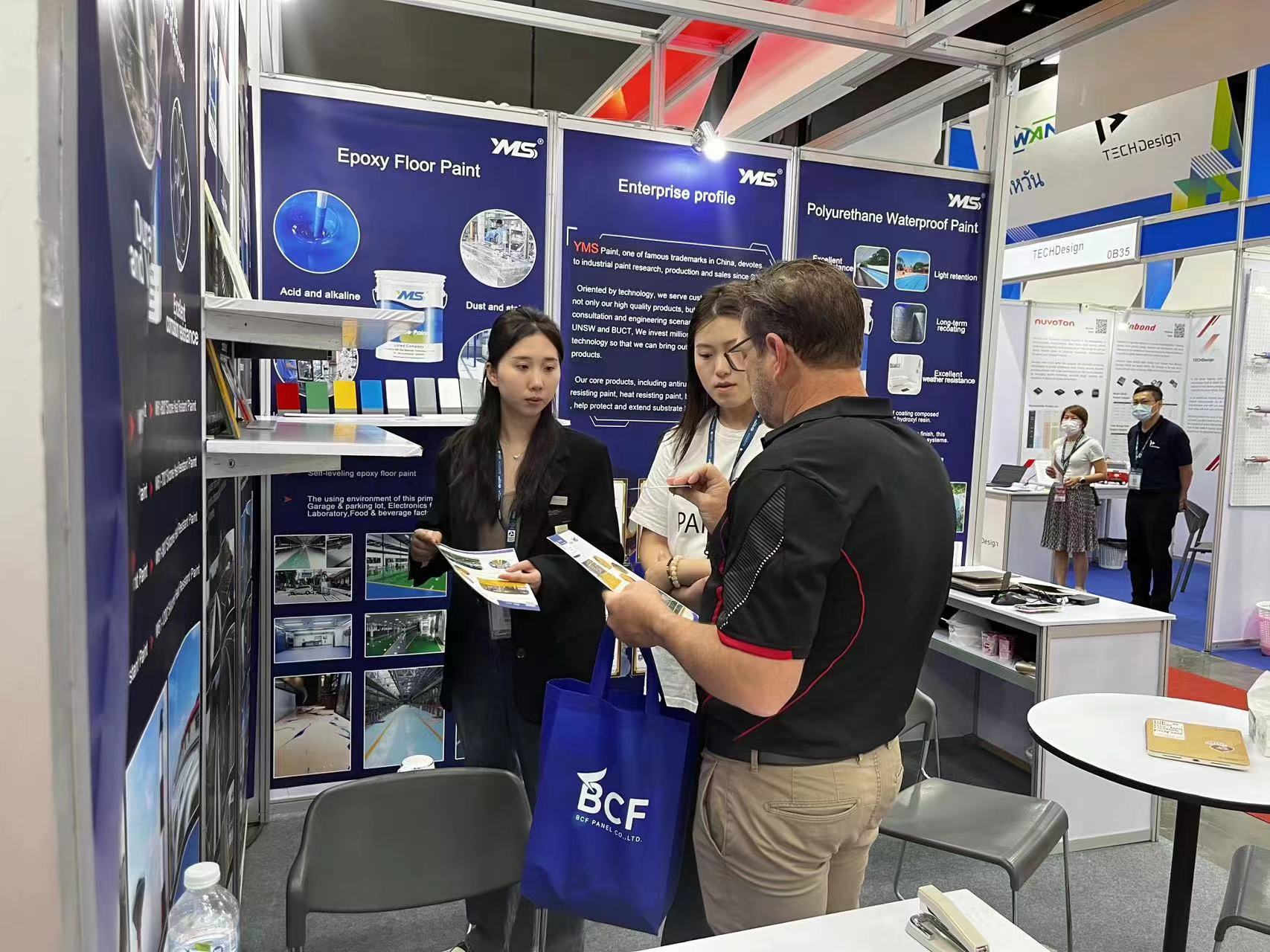

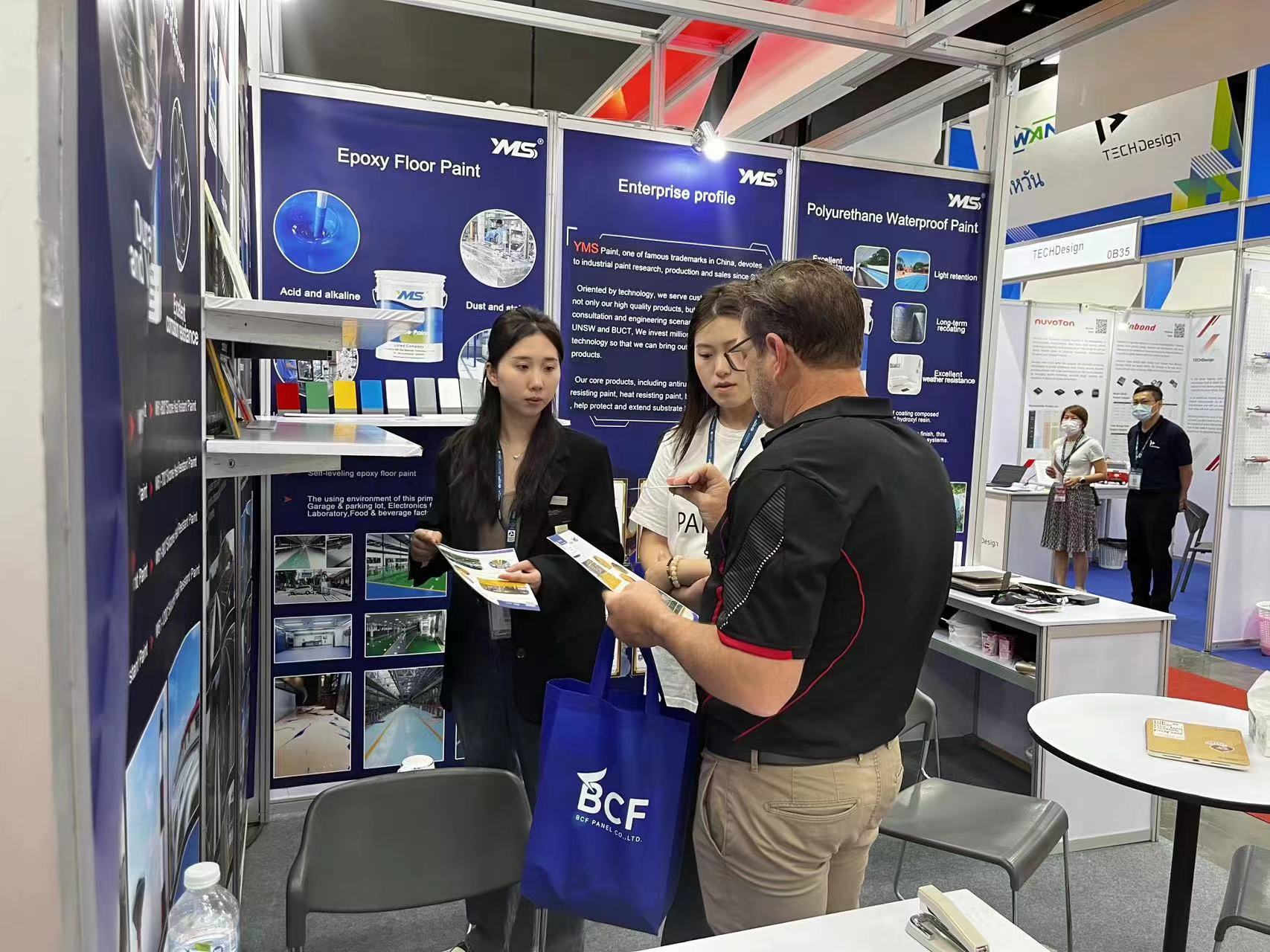

| Epoxy Coal Tar Company Profile

YMS Paint, one of famous trademarks in China, devotes to industrial paint research, production and sales since 2001.

Oriented by technology, we serve customers worldwide not only our high quality products, but also technical consultation and engineering scenarios. Cooperating with UNSW and BUCT, We invest millions to update our technology so that we can bring out better and cheaper products.

Our core products, including antirust paint, acid & alkali resisting paint, heat resisting paint, building & floor paint etc., help protect and extend substrate life for years.

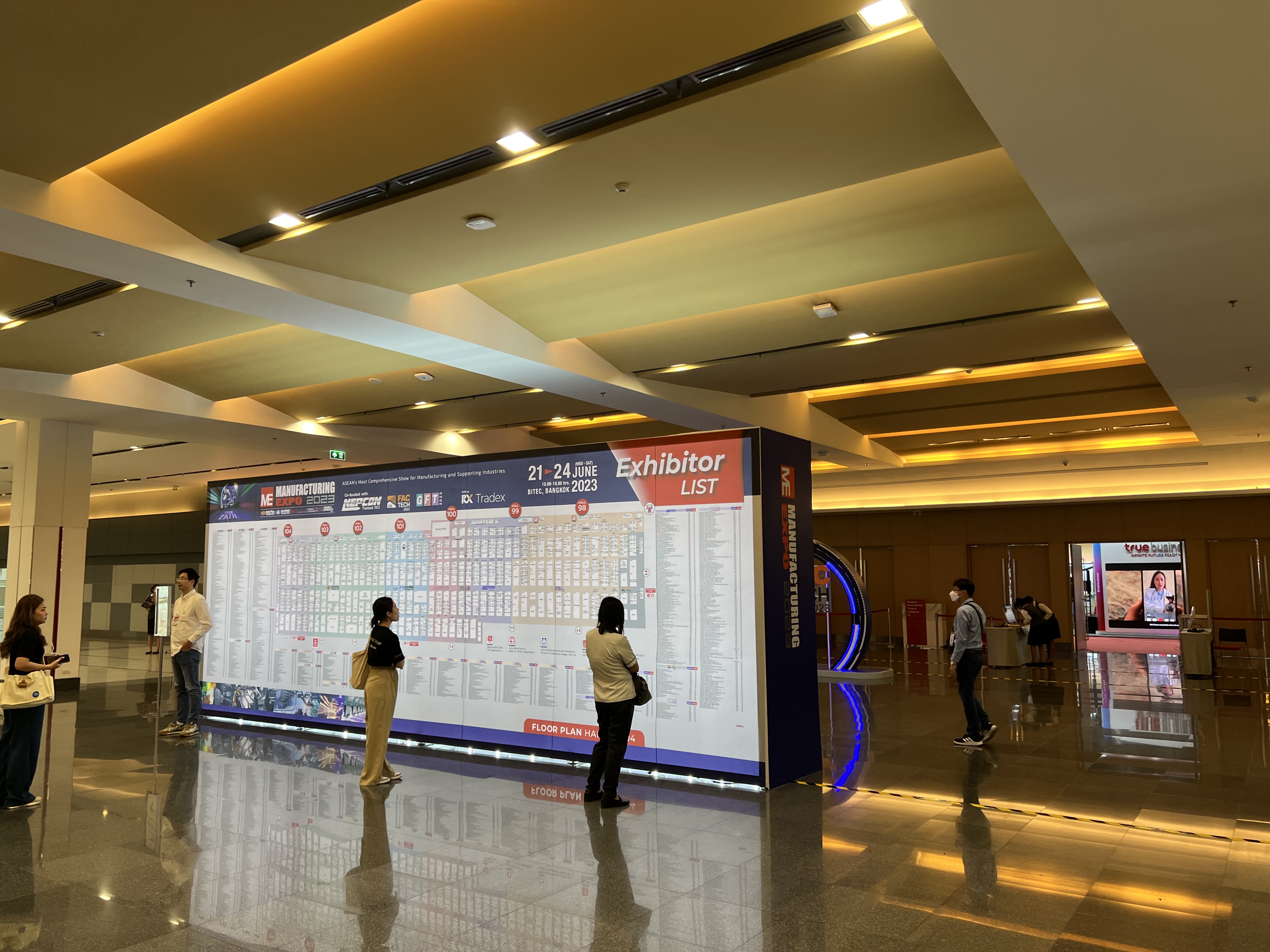

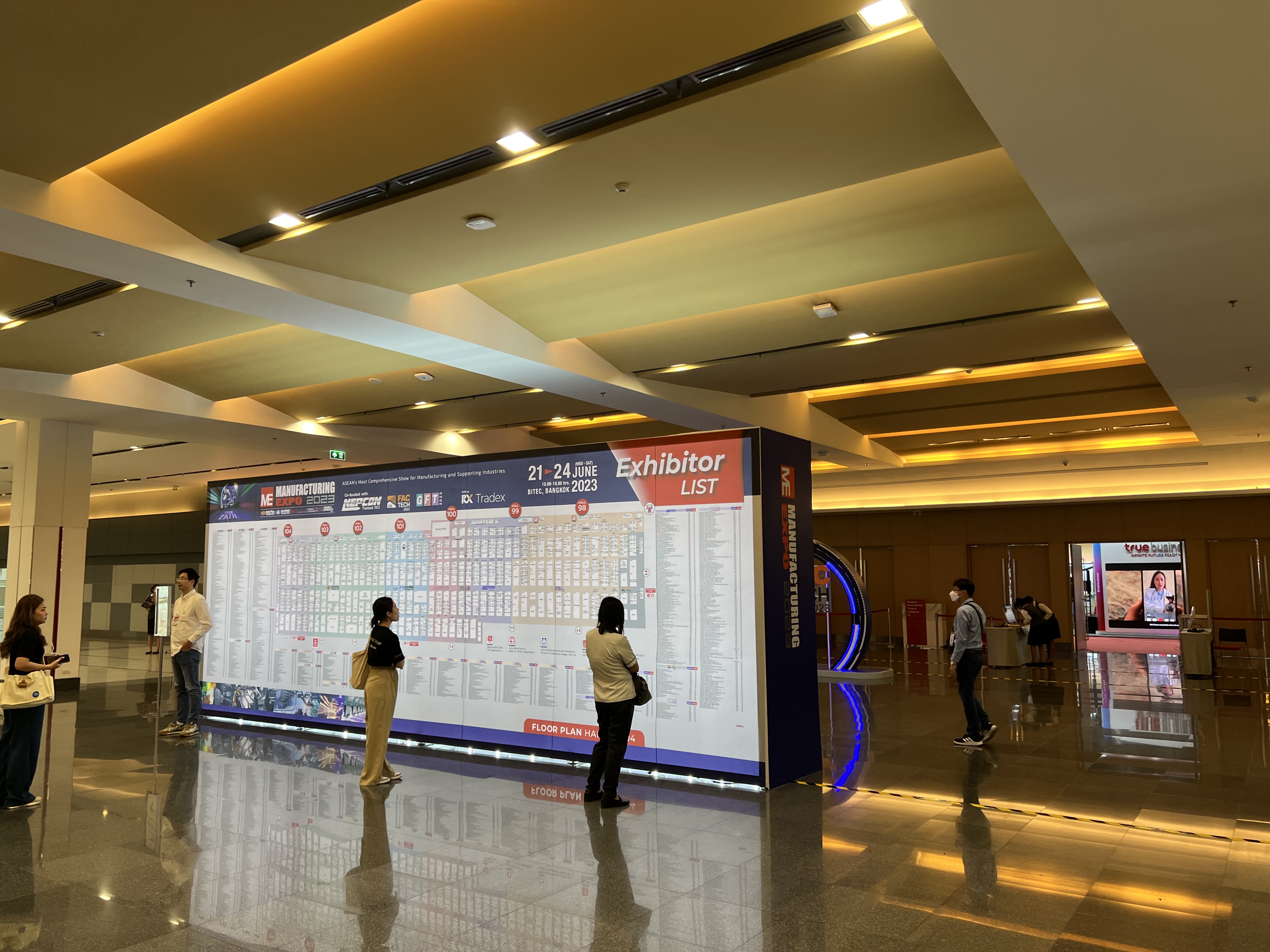

| Epoxy Coal Tar Exhibitions

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

Беларуская мова

Basa Jawa